Quality Policy

The quality management philosophy at LRW includes:

- Motivation & commitment of the employees

- Concentration on value creation work

- Acknowledgement of quality & traceability of all work done

- Continuous improvement of product and processes

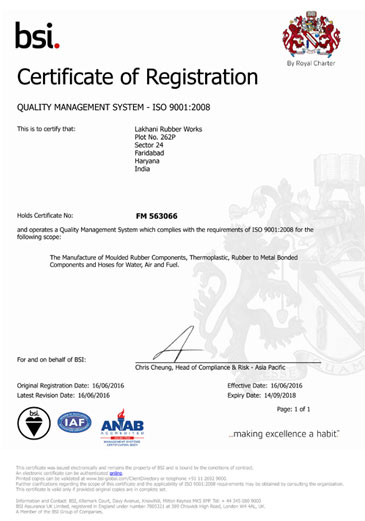

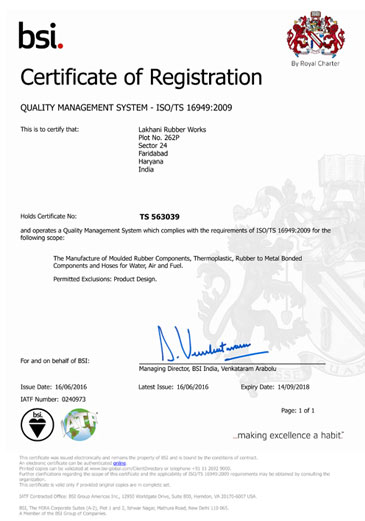

LRW’s continuous improvement in quality performance has resulted into the implementation of an irrefutable Quality Management System, which have been acknowledged by BSI Management System, in the form of TS 16949:2009 certifications, ISO 9001 & ISO 14001 & Working Towards OHSAS 18000. The company meticulously adheres to some of the best quality practices like 5-S, Kaizen, TPM, Quality Circles, Suggestion Schemes and Cross Functional Teams etc. which strengthen its motto of perusing a company-wide continuous improvement philosophy with overall focus on achieving total customer satisfaction

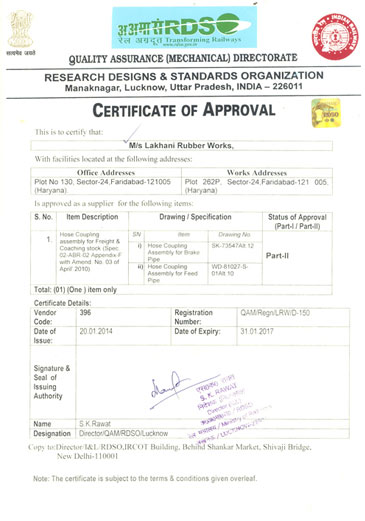

Certifications

Testing

The Physical Laboratory at Lakhani Rubber Works is equipped with Mechanical Tensile Machines, Compression Set Apparatus, Electric Ovens, Flexion Testing Machine for 180 motion, Flexion Testing Machine for 90 motion, Ph Meter, Ageing Oven, Muffle Furnace, Direct Sp. Gravity Reading Instrument, Electronic Tensile Testing M/C, Mooney Viscometer, Realence Tester, IRHD Hardness Tester, Ozone Tester, Electric Balance 10 Kgs (0.001 lacs), and Rheometer.

The Chemical Laboratory is equipped with Gravemetric & Volumetric Test Equipment, Circulatory Type Thermostatically Control Water and Electric Balance equipment.

For Dimensional Measurement, Digital and Pressure Vernier Caliper, Micrometer, Height Gauge and Surface Plate is used while The Product Test Division has installed the following testing equipment:

- Multiple Dynamic Test Machine For Bump Stopper & Endurance Test

- Endurance Test Machine - Steering Boot

- Endurance Test Machine - CVJ Boot

- Endurance Test Machine - For Hoses

- Flexing Test machine Product

- Low Temperature Testing Machine

- Burst Pressure Tester

- Leakage Test Equipment

- Endurance Testing M/C for Mounting Set Muffler

- Pulsating Vacuum Tester

The company has full-fledged power backup having installed three Gen Sets with 275 KVA and 590 KVA capacities.